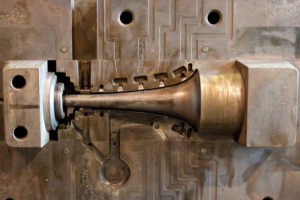

Aluminum Die Casting Alloys

Custom Aluminum Die Casting Services in North America

What do you need from your aluminum die casting partner? Die casting services tailored to increase the productivity and efficiency of your business.

At Simalex, we’re here to cater to your requirements, delivering aluminum die casting at a significantly decreased lead and cycle times with first-piece success.

Our guarantee, you get the premium quality aluminum metal castings in North America at the most affordable rates. Our highly competitive die casting services have enabled many previously machined parts to be manufactured in die casting economically.

With up to a 300-tonne hot chamber capacity and 900-tonne cold chamber capacity, we’re well-equipped to produce die casting parts for your industrial activities. Our team of technical experts and engineers help you throughout the project — from planning to installation to support.

If you’ve any questions for us or if you need a quick quote for our die casting services, just fill the form on your right, and our team will connect with you in no time.

Aluminum Die Castings for Every Industry

Aluminum gives a significant advantage to mechanical designers. Aluminum castings from Simalex are versatile and can be tailored to the demands of any business. With our in-house tooling shop, we serve construction, heavy machinery, railway and other industries. You can expect precision die casting services starting from design and tooling to finishing and machining.

Discuss and review your requirements, assessing the feasibility of the part design. Once you give us complete insight into your project, we can evaluate in advance if the tool needs removable inserts that can save time and decrease maintenance cycles.

Advantages of Working with Aluminum Alloy

With a specific gravity of approximately 2.7g/cc, aluminum alloys are amongst the lightweight structural metals. They are the popular die casting metals because of economic costs. In fact, most die castings, worldwide, are aluminum alloys.

Aluminum alloys typically involve six other elements: silicon, copper, magnesium, iron, manganese, and zinc. Each affects the metal independently and interactively. Common aluminum alloys are Alloy A380, Alloy A383, Alloy A360.

Aluminum metal castings are known to withstand the highest operating temperatures and are extremely lightweight. Besides, there’re some incredible qualities of aluminum that makes it the most suitable choice, such as:

- Corrosion resistance

- Great strength and rigidity

- Considerable strength-to-weight ratio

- Outstanding EMI and RFI shielding properties

- Excellent thermal conductivity

- Great electrical conductivity

- Strong finishing characteristics

- Full recyclability

Why Choose Simalex for Aluminum Die Castings Alloys?

GET YOUR QUOTE NOW

Got a project in mind? Whether you’re at a conceptual stage or you already know exactly what you want, whether it’s a large or a small run, get in contact with us. We can’t wait to hear about it!