Magnesium Die Casting Alloys

Custom Magnesium Die Casting Services in North America

Does your project require lightweight die casting components with an excellent strength-to-weight ratio? Magnesium Die Casting alloys are the logical options.

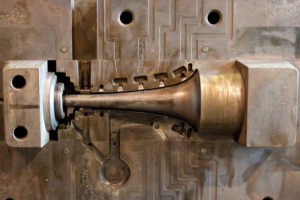

At Simalex, we offer you high-purity magnesium alloy parts that provide excellent corrosion resistance with great finishing. Our hot chamber with 300-tonne capacity can produce die casting parts that are tailored to your exact requirements.

The manufacturing process takes advantage of magnesium’s excellent flow characteristics to produce complex shapes that serve different industries perfectly.

Simalex has the most advanced manufacturing facility in North America, driven by industry-leading design and engineering prowess. We help you choose metal casting alloys based on the environment the part will function and its performance requirements.

Additionally, our team provides you with several options for tooling and prototyping of magnesium die casting parts with various lead times and tool life available to meet your program schedules.

Don’t sacrifice on durability with precision magnesium die casting! Get in touch with our team by filling the form on your right and get a quote for our die casting services.

Magnesium Die Castings for Every Industry

At Simalex, we’re capable of producing the custom die casting parts that weight up to 2 pounds. Our team has extensive experience working with magnesium alloys in industries producing power tools, ATV’s, computers, railway, and medical devices.

We are known for the quick production process, precision and high-quality castings, which has helped in the continued expansion of magnesium casting applications in the aerospace, electronics and lighting industry.

Advantages of Working with Magnesium Alloy

With its specific gravity 1.74g/cc, magnesium is the lightest commonly used structural metal. The most used magnesium alloy for die castings is AZ91D. With excellent stiffness and strength-to-weight ratios, magnesium die casting alloys are very cost-effective in comparison to other engineered thermoplastic materials. Here are some of the advantages of working with a magnesium die castings:

- High electrical and thermal conductivity

- Withstands high operating temperatures

- Excellent dimensional accuracy and stability

- Outstanding EMI and RFI shielding properties

- Great thin wall capability

- High environmental corrosion resistance

- Unique finishing characteristics

- Full recyclability

AZ91D alloy has an excellent combination of mechanical properties, corrosion resistance, and castability. Magnesium metal alloys have the best machinability of all commercially used metal alloys. For surface treatments, magnesium alloys can receive decorative chromate treatment, painting, plating, and phosphate coatings.

Why Choose Simalex for Magnesium Die Castings Alloys?

GET YOUR QUOTE NOW

Got a project in mind? Whether you’re at a conceptual stage or you already know exactly what you want, whether it’s a large or a small run, get in contact with us. We can’t wait to hear about it!