Blog

VENTILATOR COVERS: CONTRIBUTING WHAT’S NEEDED RIGHT NOW

At Simalex, we produce a variety of parts and essential components for different industries, and we pride ourselves in the versatility and accuracy of our parts. Recently, our production has seen a significant change due to the rising demand in medical ventilators for CoVid-19 patients in intensive care. Keep reading to see how we’re adapting ... Read moreVENTILATOR COVERS: CONTRIBUTING WHAT’S NEEDED RIGHT NOW

ALUMINUM: A VIABLE ALTERNATIVE TO MAGNESIUM DIE CASTING

Die Casting is one of the most cost-effective and versatile manufacturing processes in the world. From durable mechanical parts for household use to complex geometrical parts for medical equipment, this precision process provides you with a part of the desired shape with incredible dimensional accuracy. When setting out the die-cast design, it is crucial to ... Read moreALUMINUM: A VIABLE ALTERNATIVE TO MAGNESIUM DIE CASTING

WHAT ARE THE KEY DESIGN DECISION STEPS FOR DIE CASTING?

The die casting process has been researched and systematically quantified in the last few years. If we talk about, die-cast design — it is 80% science and 20% art. The designers have an added responsibility for optimizing the costs and performance equation of a new or redesigned product. There are a lot of different aspects ... Read moreWHAT ARE THE KEY DESIGN DECISION STEPS FOR DIE CASTING?

3 WAYS FOR QUALITY ASSURANCE IN CUSTOM DIE CASTING

Continuing advances in die-cast processing and control technologies have helped die casters to achieve high levels of precision in the last few years. Also, the production capabilities of the die casters have increased multifold. Now, the customers can put forward the custom die casting requirements and remain assured that die casting companies will align it with their projected ... Read more3 WAYS FOR QUALITY ASSURANCE IN CUSTOM DIE CASTING

USING ALUMINUM DIE CASTINGS FOR ELECTRONIC ENCLOSURES

Are you in need of electronic enclosures? Many industries are — from rail to construction and manufacturing to marine equipment. While these enclosures can be plastics or various kinds of steel, the die casting material of choice is often aluminum. Read on to find out why aluminum die castings are the popular choice for electronic ... Read moreUSING ALUMINUM DIE CASTINGS FOR ELECTRONIC ENCLOSURES

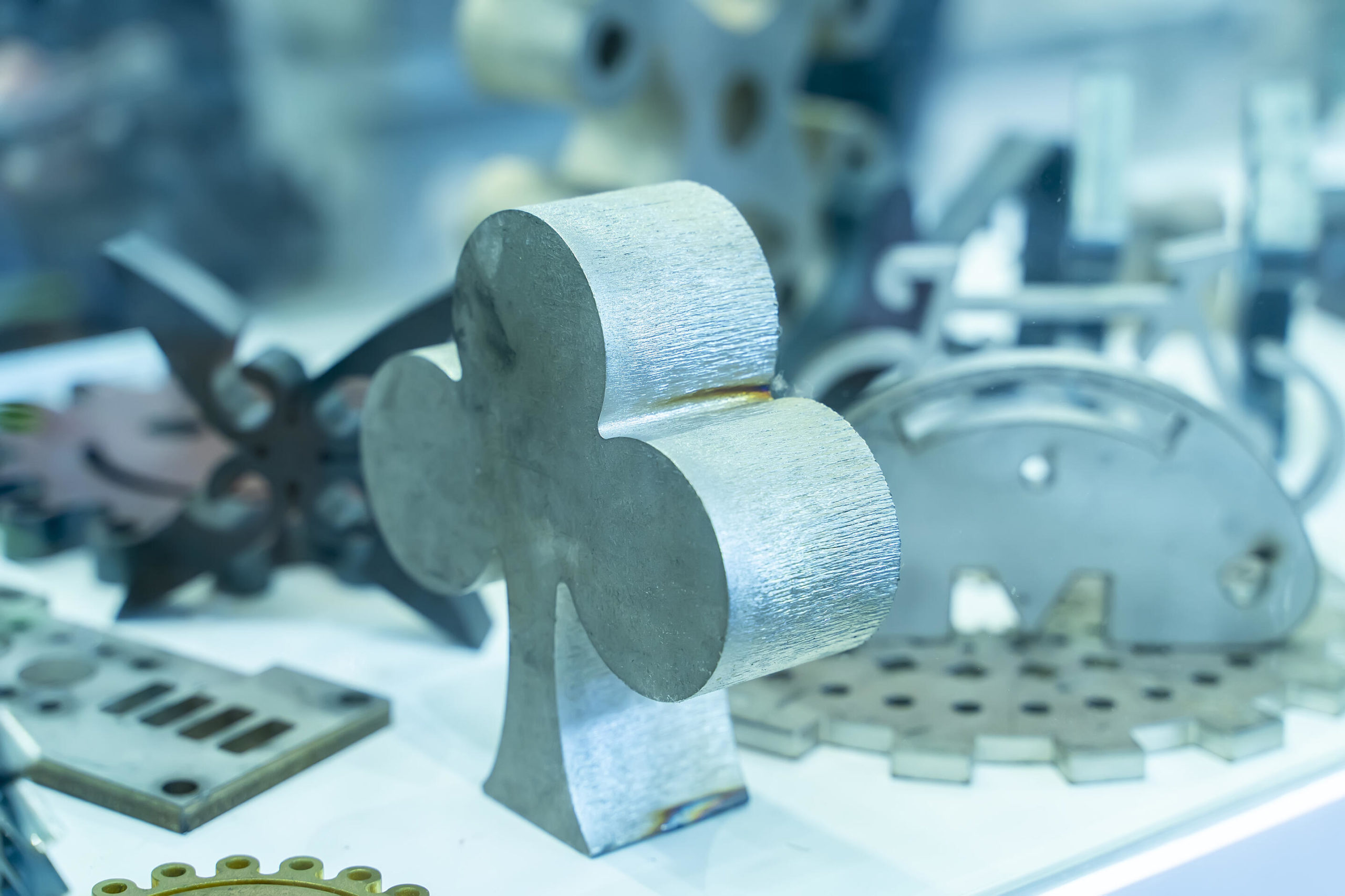

THE DIE CASTING MANUFACTURING PROCESS

What are you trying to solve? When a company contacts Simalex, they’ll share the parts they need and the bigger challenge they’re seeking to solve. What that looks like can be anything from a phone call describing the intent of what they’re looking for to a fully scaled 3D model that’s already been produced as ... Read moreTHE DIE CASTING MANUFACTURING PROCESS

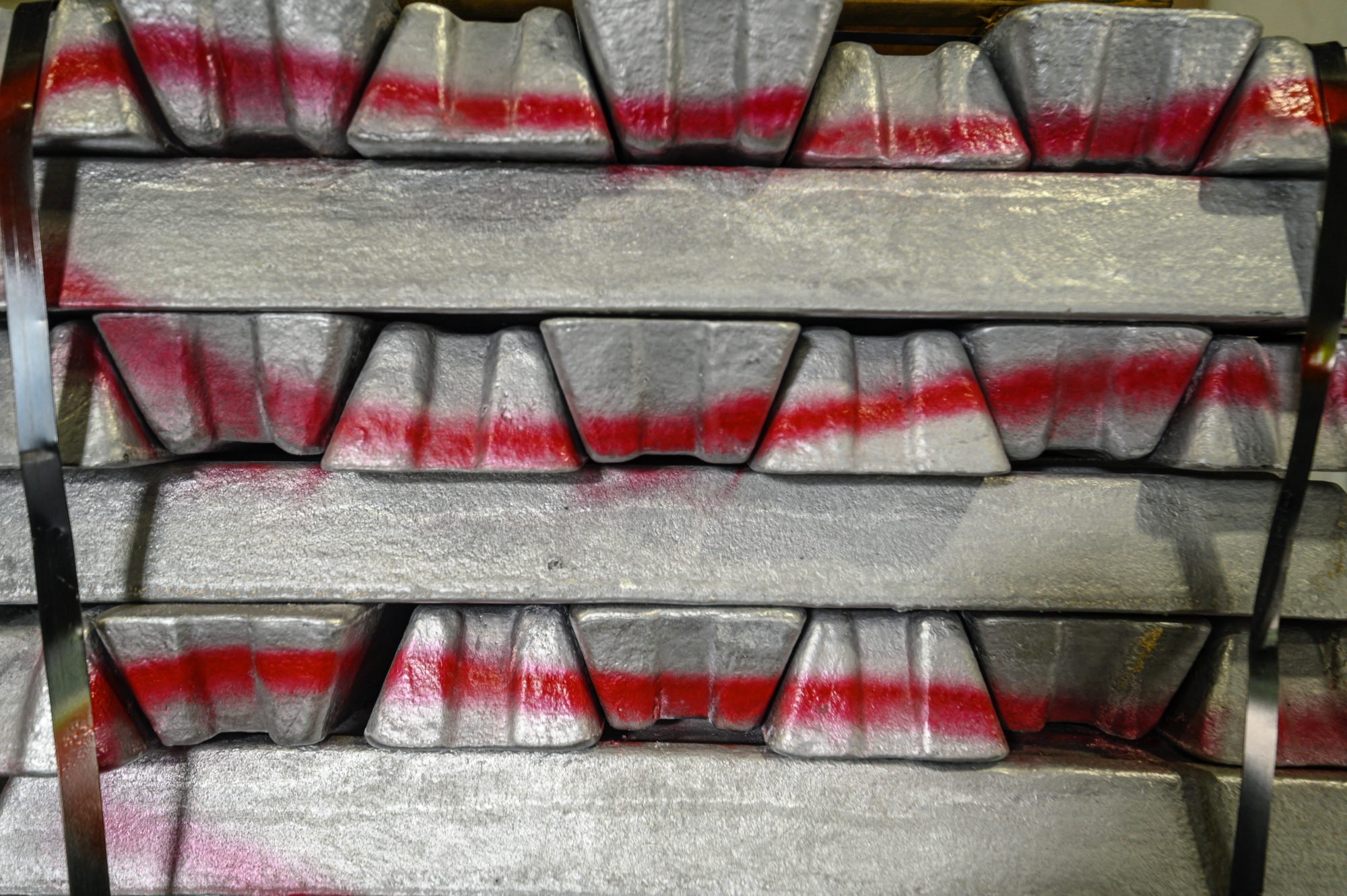

WHAT METALS AND ALLOYS ARE COMMONLY USED IN DIE CASTING?

One of the strengths of die casting is the ability to leverage a variety of alloys in the process according to the needs of the part. HERE, WE’LL DISCUSS THE ADVANTAGES AND DISADVANTAGES OF THREE COMMON GROUPS OF ALLOYS: ALUMINIUM, MAGNESIUM, AND ZINC. You’ll see that no matter what you’re looking for, there’s very often ... Read moreWHAT METALS AND ALLOYS ARE COMMONLY USED IN DIE CASTING?

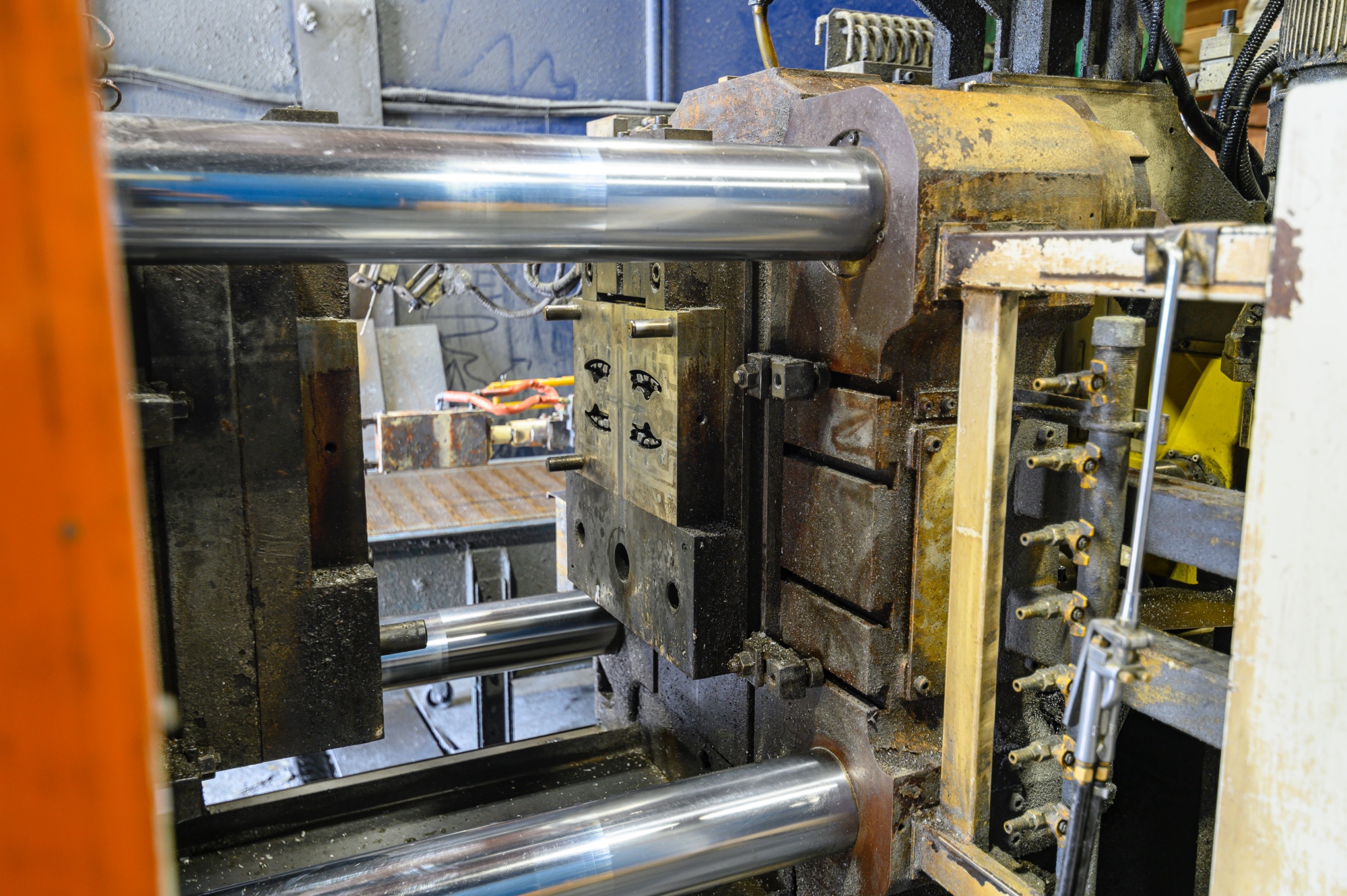

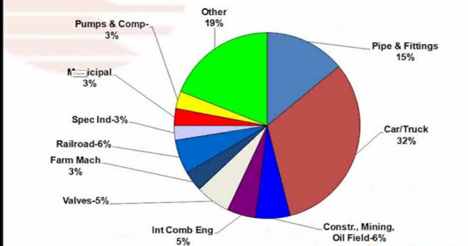

WHAT IS DIE CASTING?

In short, die casting is the method of injecting liquid metal into a reusable steel mold or die, very quickly, under high pressure. Its advantages are very attractive for many use cases. While there are start up costs, once the die is in production, it’s possible to produce a large number of parts swiftly, affordably ... Read moreWHAT IS DIE CASTING?

MACHINING OR DIE CASTING: HOW TO CHOOSE

Die casting and machining both produce high quality parts, but depending on your project’s specifications, it may make sense to use one process more than the other. BENEFITS OF DIE CASTING Lowest cost-per-piece for high volumes (10,000+ pieces) Provides the smoothest finish Allows for thinner walls and tight tolerances BENEFITS OF CNC MACHINING Automated, high ... Read moreMACHINING OR DIE CASTING: HOW TO CHOOSE

ARE YOU STRATEGICALLY PLACING YOUR PARTING LINE?

How much thought are you giving to the placement of your parting line for die cast parts? “The parting line of a die cast component represents where the two different sides of the mold come together. This line often (but not always) marks the border between the inside and outside of the part” Poorly located ... Read moreARE YOU STRATEGICALLY PLACING YOUR PARTING LINE?

Recent Posts

Posted on June 6, 2023

Posted on June 29, 2022

Posted on June 29, 2022

Posted on June 29, 2022

Posted on June 29, 2022